Sustainable Practices in Transformer Oil Recycling for a Greener Future

Effective and Liable Approaches for Reusing Transformer Oil

The recycling of transformer oil is a critical yet often neglected facet of energy management and environmental defense. Methods such as innovative filtering and chemical treatment not just improve oil quality however also alleviate the environmental hazards linked with improper disposal.

Importance of Recycling Transformer Oil

By recycling transformer oil, firms can minimize these environmental risks while also taking advantage of economic benefits. Redeemed oil can be dealt with and recycled in numerous applications, reducing the requirement for new oil manufacturing, which in turn conserves natural resources and reduces greenhouse gas emissions related to oil removal and refining procedures. This practice not only advertises lasting resource administration yet additionally reduces operational expenses for businesses.

Techniques of Transformer Oil Recycling

Reusing transformer oil involves numerous effective techniques that guarantee the safe and efficient recuperation of valuable resources while minimizing environmental influence. One key technique is filtering, which eliminates particle pollutants and water from the oil, restoring its physical residential properties. This process is usually improved by utilizing vacuum cleaner dehydration and fine filtering techniques, which can dramatically boost the oil's top quality.

Another method is chemical treatment, where additives are made use of to neutralize acids and damage down damaging compounds. This procedure commonly consists of making use of clay absorbents or chemical representatives that can assist recover the oil to its initial efficiency criteria.

Thermal therapy, consisting of distillation, is likewise used to divide various elements of transformer oil, enabling the recuperation of base oils for reuse - Transformer Oil Purification. This approach is particularly reliable for oils that have actually weakened considerably

Finally, re-refining processes convert made use of transformer oil back right into top notch base oils ideal for new products. By applying these recycling methods, the sector can not only minimize waste but also advertise sustainable practices that add to source conservation and ecological defense. Each technique provides special advantages, making them necessary parts of an effective transformer oil reusing strategy.

Governing Standards and Compliance

Browsing the governing landscape surrounding transformer oil recycling is crucial for making sure conformity and promoting environmentally liable methods. Numerous guidelines regulate the handling, storage, and disposal of transformer oil, mainly due to its possible unsafe nature. In many areas, transformer oil is classified as a contaminated materials, demanding adherence to specific regulatory frameworks, such as the Source Conservation and Recuperation Act (RCRA) in the United States.

Organizations must understand regional, state, and government guidelines that dictate the correct recycling approaches and the paperwork required for compliance. Obtaining required licenses for transport and recycling processes is often mandated. Furthermore, the United State Environmental Defense Agency (EPA) and similar bodies in various other countries give standards to make sure that transformer oil is processed in a way that decreases ecological dangers.

Compliance likewise involves routine audits and training for employees taking care of transformer oil to ensure they understand and comply with recognized methods. Transformer Oil Recycling. Failure to abide by these guidelines can lead to legal effects and considerable fines, highlighting the value of remaining updated on transforming regulations and best practices in transformer oil recycling. Guaranteeing compliance not just safeguards the atmosphere yet additionally improves company obligation and public trust fund

Ingenious Technologies in Recycling

Developments in cutting-edge innovations have actually considerably transformed the landscape of transformer oil recycling, enhancing both effectiveness and sustainability. One notable development is making use of advanced filtering systems that use nanotechnology to get rid of pollutants and impurities. These systems can achieve higher filtration levels than standard approaches, ensuring the oil satisfies rigid quality criteria for reuse.

Furthermore, the assimilation of automation and synthetic intelligence in recycling processes Read Full Report has streamlined operations. Automated systems display and optimize the reusing process in real-time, reducing human error and functional prices. Anticipating analytics can forecast tools upkeep needs, lessening downtime and maximizing throughput.

Lastly, the growth of bioremediation techniques, utilizing bacteria to weaken toxins in transformer oil, Resources showcases a novel strategy to recycling that aligns with lasting practices. Jointly, these innovative modern technologies are leading the way for extra effective, liable, and environmentally-conscious transformer oil recycling procedures.

Benefits of Accountable Recycling Practices

While the environmental benefits of responsible reusing practices are commonly highlighted, the economic benefits are just as significant. Applying efficient recycling approaches for transformer oil can cause substantial expense financial savings for organizations. By recycling made use of oil rather than buying brand-new supplies, firms can decrease functional expenditures and enhance their revenue margins.

In addition, responsible recycling methods can develop job chances within the area, as specialized facilities are needed to handle the collection, handling, and circulation of recycled transformer oil - Transformer Oil Recycling. This not just boosts local economies yet additionally advertises sustainable development

Furthermore, adhering to accountable recycling guidelines aids companies adhere to regulatory Learn More Here demands, consequently staying clear of potential fines and legal difficulties connected with improper disposal. This compliance can boost a firm's track record, cultivating trust fund amongst stakeholders and customers.

Moreover, the method of reusing transformer oil adds to source preservation by minimizing the demand for virgin materials, consequently minimizing the ecological footprint connected with oil manufacturing. Organizations that focus on accountable recycling not only strengthen their company social duty efforts but also place themselves as leaders in sustainable techniques within their market. Generally, the multifaceted advantages of liable recycling practices are obvious and crucial for both economic and environmental sustainability.

Verdict

The recycling of transformer oil is essential for environmental defense and resource conservation. Using advanced filtering, chemical treatments, and thermal handling not only brings back oil top quality but likewise minimizes hazardous waste dangers.

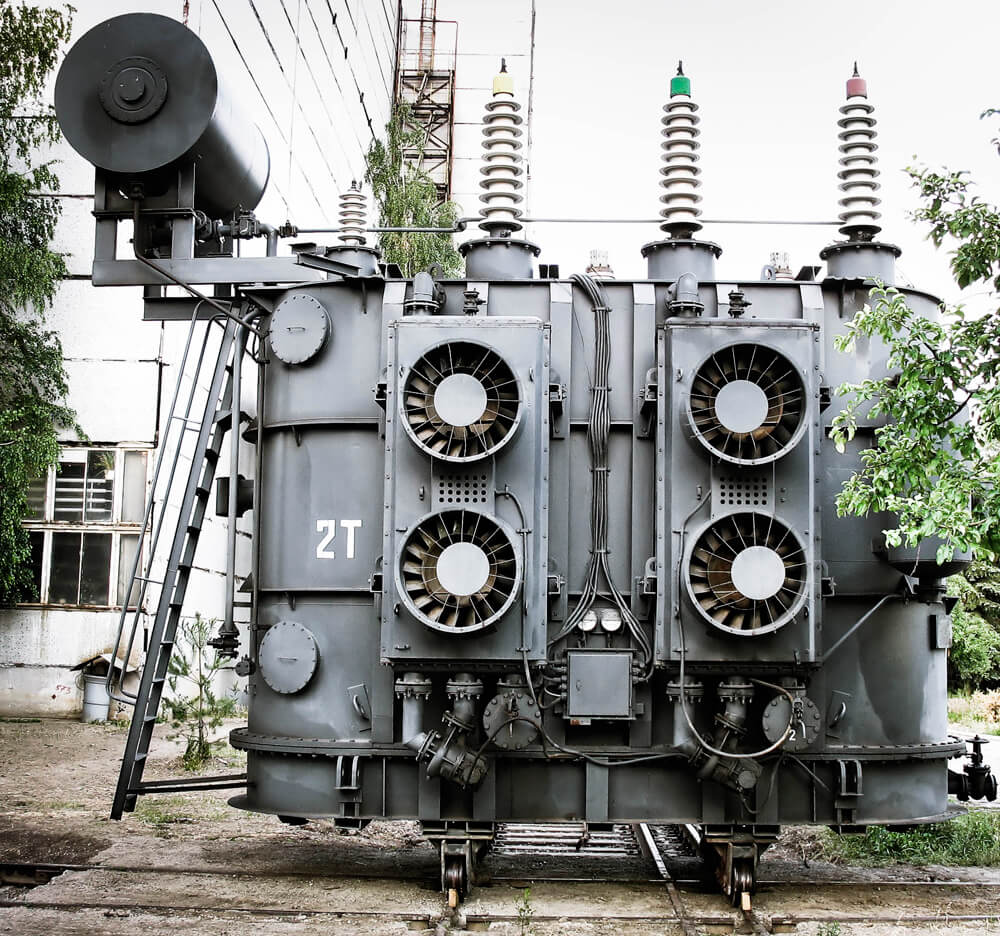

Transformer oil, largely used in electrical transformers for insulation and air conditioning, postures significant environmental dangers when poorly disposed of. Reclaimed oil can be treated and reused in different applications, lowering the need for new oil manufacturing, which in turn decreases and saves all-natural sources greenhouse gas exhausts connected with oil removal and refining procedures.Reusing transformer oil entails numerous reliable methods that ensure the risk-free and effective healing of important resources while reducing environmental effect. Carrying out effective recycling techniques for transformer oil can lead to significant cost savings for companies.Furthermore, the technique of reusing transformer oil adds to source preservation by minimizing the demand for virgin materials, thus reducing the environmental footprint linked with oil manufacturing.